By Ian Gregory Bigger (Team Lead) and Steven D. Carreon (Asst. Team Lead)

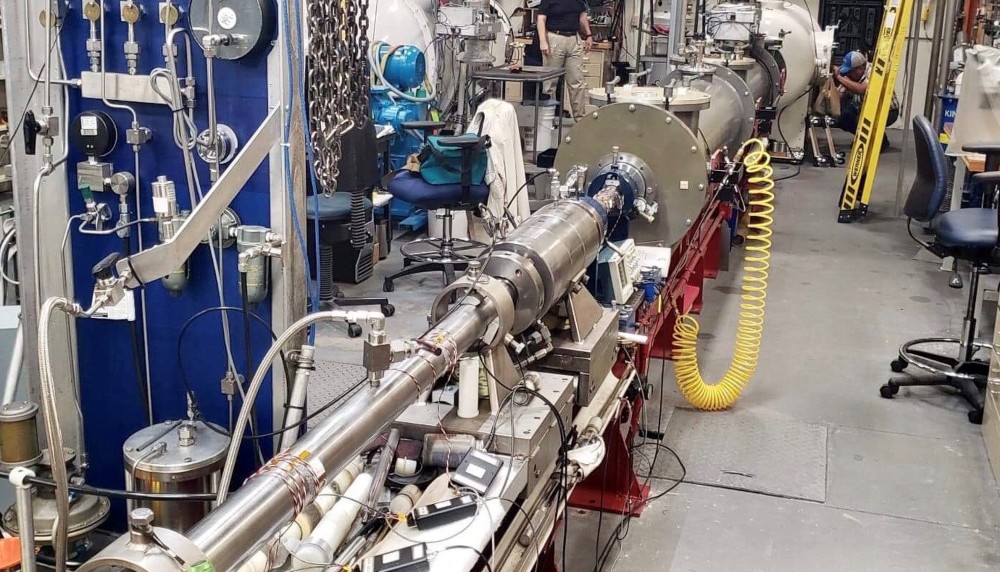

During the prior semester, Fall 2019, our team, Zero-G, was generously invited by Dr. Phillip Anz-Meador of NASA’s Orbital Debris Program Office at Houston Johnson Space Center to conduct hyper-velocity impact tests for Project ORION (Orbital RemediatION) at the Experimental Impact Laboratory. The testing allowed us to gain experience with several different orbital debris shields commonly used on the ISS as well as experimental shields. This data would be used to determine which shield type would be most appropriate for a sweeper debris satellite intended to clean debris fields in low earth orbit that pose as a threat to current functional satellites. Testing was supervised by lab director Dr. Mark Cintala, and test engineers Frank Cardenas and Roland Montes. Our trip to Houston was accompanied by our highly esteemed capstone professor, Dr. Daniel White, and lasted through November 7th to the 9th.

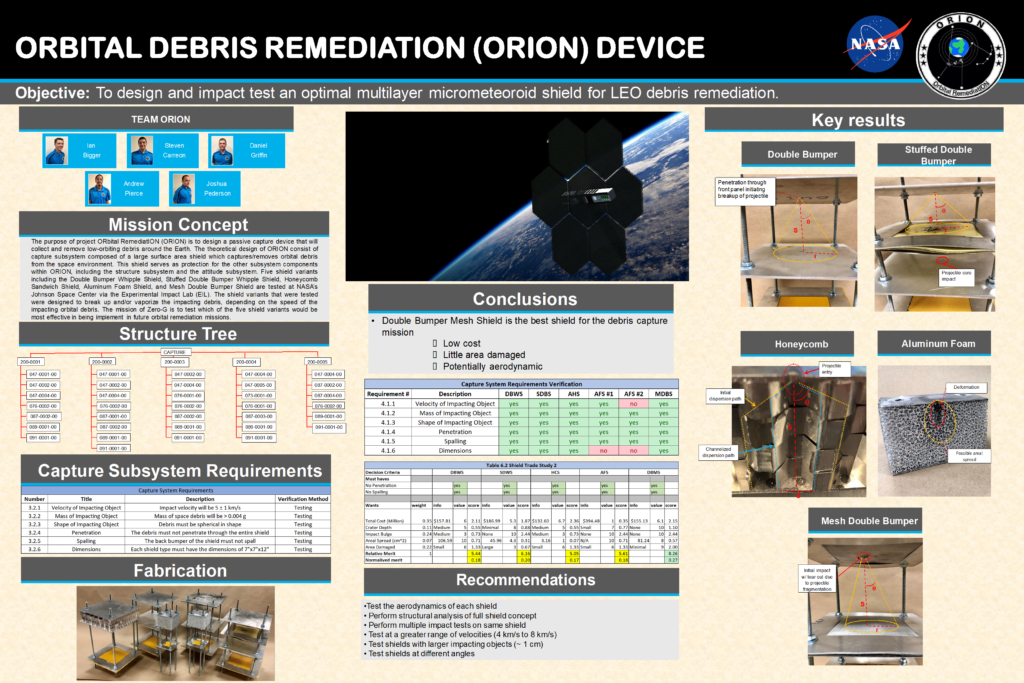

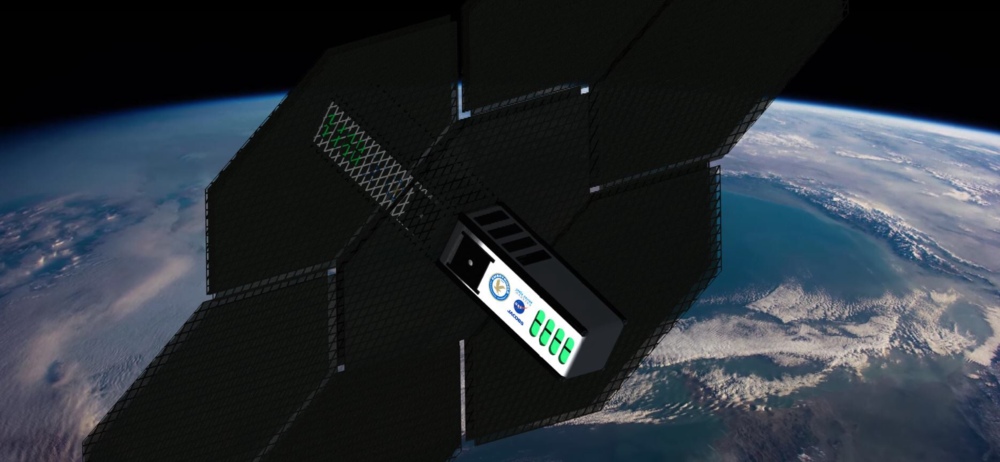

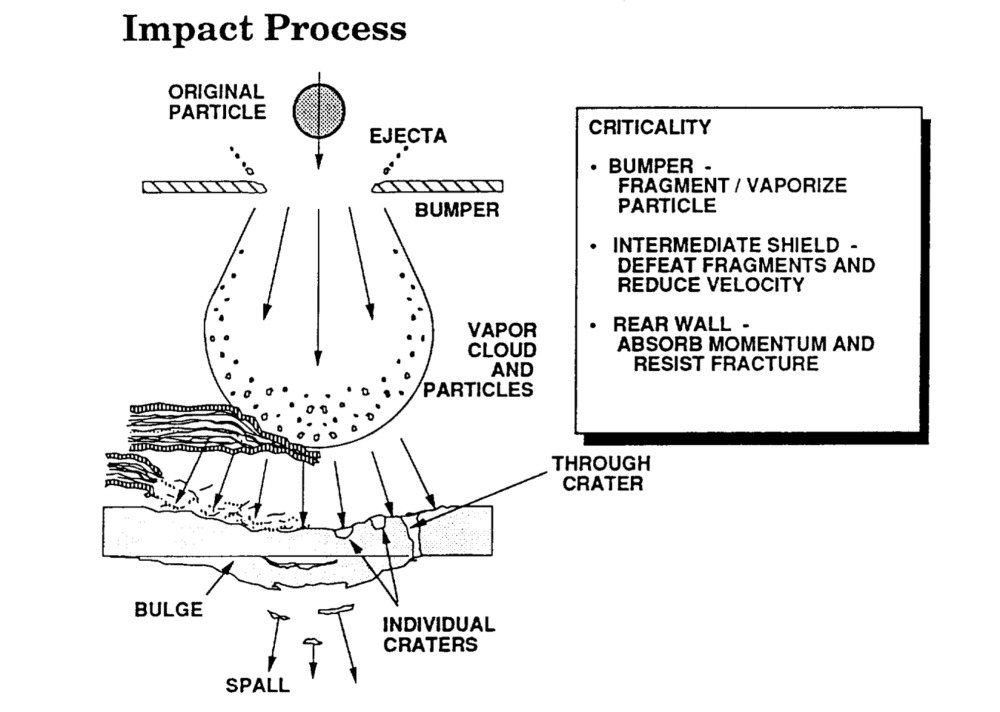

The change in design of ORION from an active satellite capable of rendezvous with large piece of orbital debris to a passive satellite intended to pass and clean small debris in high debris orbits originated from Ian Bigger’s Summer 2019 internship at the Orbital Debris Program Office at Johnson Space Center. As a team, we decided implement multi-layered micrometeoroid orbital debris shields, the current method that most large spacecraft implement for defense against orbital debris.

Entering the Fall 2019 semester came with a complete revamp of our capstone project’s preliminary design along with many difficulties. Through multiple iterations of our team’s design, we were able to create a project that became feasible and fulfilled our project requirements. In doing this, we attracted the attention of the Hypervelocity Impact Test Lab, allowing us to test an experimental orbital debris shield composed of two panels of steel mesh.

Our team decided to test five shield variants that could one day be re-purposed for intentionally impacting Low Earth Orbiting debris. This method of passive orbital debris remediation had never been tested up to the point of our detail spacecraft design commencement. One of the shield variants chosen (aluminum foam) was outside of our team’s budget. After notifying Dr. Philip Anz-Meador of our team’s financial limitations, he amazingly and surprisingly offered to find and donate an aluminum foam block (6” x 6”) to us, courteous of NASA. The block had an approximate value of $800.

We had a smooth flight to Houston and arrived the night of November 7th. After situating in our own respective hotel rooms arranged by ERAU, we went out for double cheeseburgers with avocado at Texas’ own Whataburger, and they were delicious. We needed all the body and mind fuel we could gather for what would become a full 8-hour day of testing at Houston Johnson Space Center the following day.

Upon arriving at Johnson Space center, we were greeted and verified for entrance by very polite, armed security guards at the South Gate, and directed to the front office to obtain our guest passes. After obtaining our guest passes, we immediately made our way to Dr. Phillip Anz-Meador’s office in the building adjacent to the Experimental Impact Laboratory. Dr. Phillip Anz-Meador was excited and cordially greeted us, and then introduced us to the building staff that would be supervising our hyper-velocity impact testing.

There was a total of six test fires conducted in the two days of testing. Four tests in the first day, and two on the second day. Preparation for each shot took approximately 1.5 hours. Between each preparatory period, we took advantage of the time by enquiring on the vast amount of test equipment and procedures within the laboratory, history of the staff with NASA, and pleasant conversations about our future plans as professional engineers.

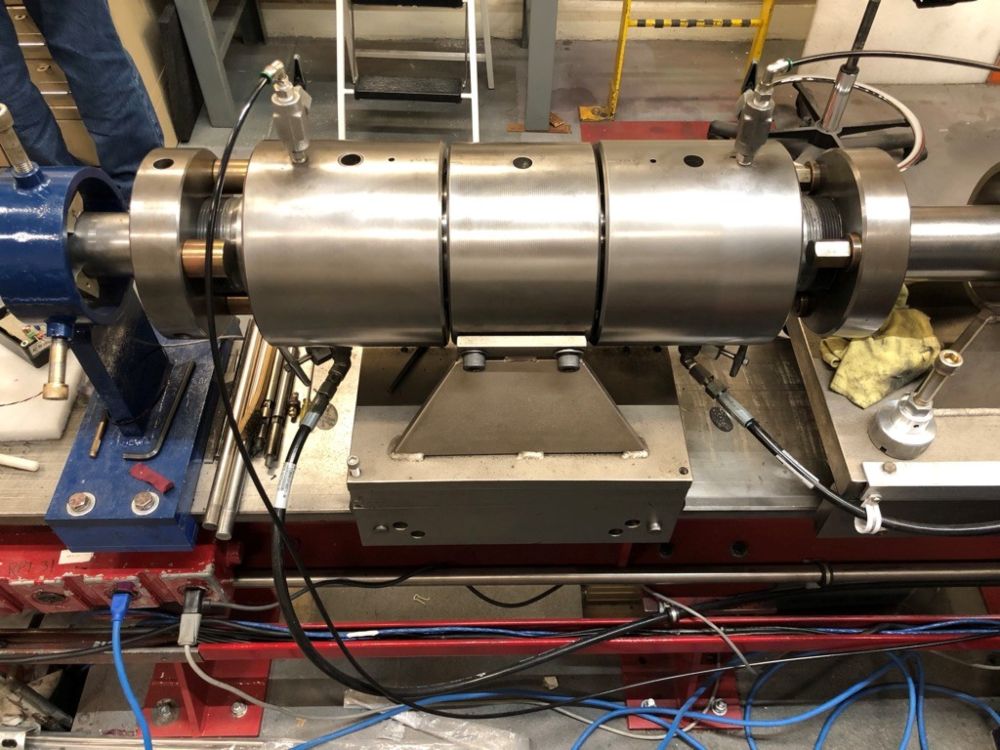

Just before a firing was about to start, the 1 mm stainless steel sphere projectile was loaded in a collapsible sabot lubricated with a graphite pencil. The loaded sabot was then loaded into the launch tube just aft of the metal diaphragm.

The compression chamber was then filled with nitrogen gas just under the point of diaphragm rupture. Once the final checks were made the entire laboratory was evacuated outside into the hallway where the key-activated firing control panel was located. The compression chamber was topped off with more nitrogen gas, then test engineer Roland Montes would flip the release switch to trigger the gun powder portion of the Light Gas Gun that would rupture the diaphragm and delivery the projectile down the chamber. A successful shot was indicated by a rapid gas hiss and audible pop over a couple milliseconds.

The velocity of each projectile was measured using a series of three laser sensors located in the launch tube about 30 inches apart from one another. Each velocity was translated using a combination of time and distance recorded by three oscilloscopes and timing devices.

The results turned out amazing and above all of our expectations for an undergraduate capstone project. We took a tremendous amount of care in manufacturing and assembling the five shield variants. No penetration occurred in any of the designs. Some of the shields did experience bulging on the rear panel, but still no spalling and no penetration.

After a successful round of tests on the second day, we were all cleared to get lunch and tour the facility. We said our farewells and went out to get more burgers at a local favorite of NASA employees, including the astronauts in training. Dr. Phillip Anz-Meador accompanied us, and on the car ride over he asked us what our plans were for the future. We received congratulations and even future job opportunities with NASA and their contractors. We even expressed our interest in top secret jobs related to orbital debris and were told to contact him in the future when we were ready for the commitment.

After a fantastic meal, we returned to Johnson Space Center to do a brief tour. With our guest passes we decided to take the Space Center Houston tour backwards to avoid the flood of tourists because we could. Dr. White and the two of us had an amazing and eye-opening experience at Johnson Space Center. As a group we learned how a professional laboratory operates, the deadlines associated, and the level of professionalism mixed with quirkiness that is required at facilities like NASA’s Johnson Space Center. We were reassured by lab engineer Frank Cardenas that in order to work with NASA, the employees all have a profound interest in their work and have fun. So much interest and fun that the clock and time seem to disappear. We learned this behavior firsthand in our time working on this capstone project, and finally realized that we were not alone in our fascination of remediating space debris during our time at NASA’s Johnson Space Center.