By Henrik Hoffmann

Hi, I am Henrik Hoffmann a rising Aerospace Engineering senior, and during my junior year I had the privilege to work on the Urban Air Mobility (UAM) project with Embry-Riddle’s Undergraduate Research Institute (URI), which was sponsored by Honeywell Aerospace for the fall and spring semester. Through the support of the URI, Dr. Johann Dorfling, and with the support of Honeywell engineers, UAMs flight testing and data analysis started at the end of our summer internship and is planned to finish during the 2020 fall semester.

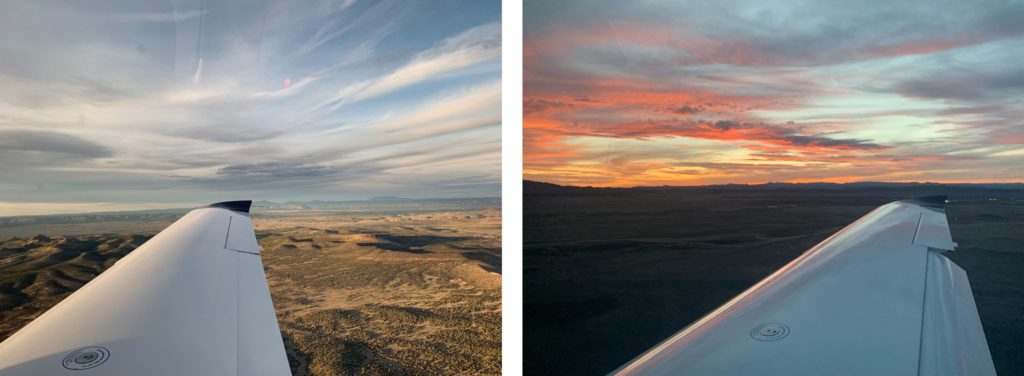

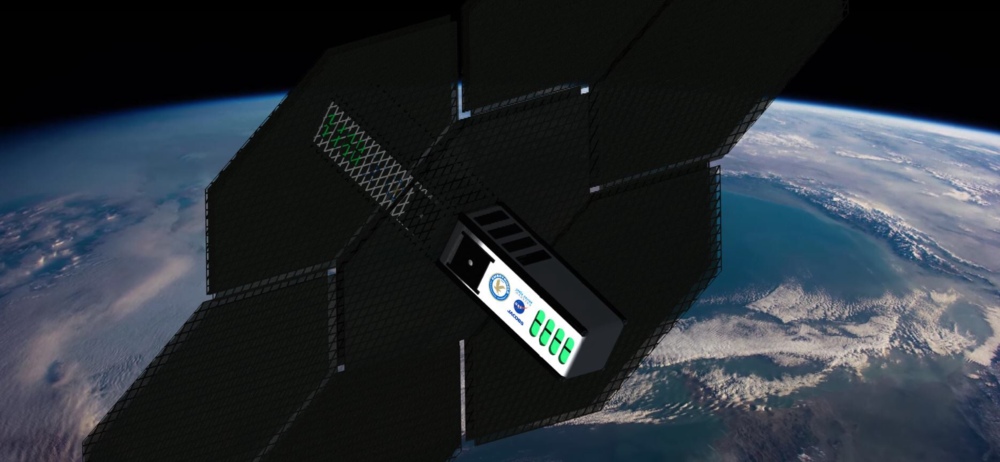

The purpose of this project for my junior school year and summer internship was to characterize the power requirements, climb profile, and descent profile capabilities of various simulated UAMs. I also helped define required UAM flight capabilities, most efficient flight paths, and UAM limitations. Multiple configurations and concepts of UAM aircraft are being proposed, designed, and built by a variety of companies such as Airbus, Joby Aviation, Kitty Hawk, Lilium, Terrafugia, Uber Air, VA-1X and Volocopter. Concepts for these UAMs include multirotor, fixed wing, and rotating rotor wing designs.

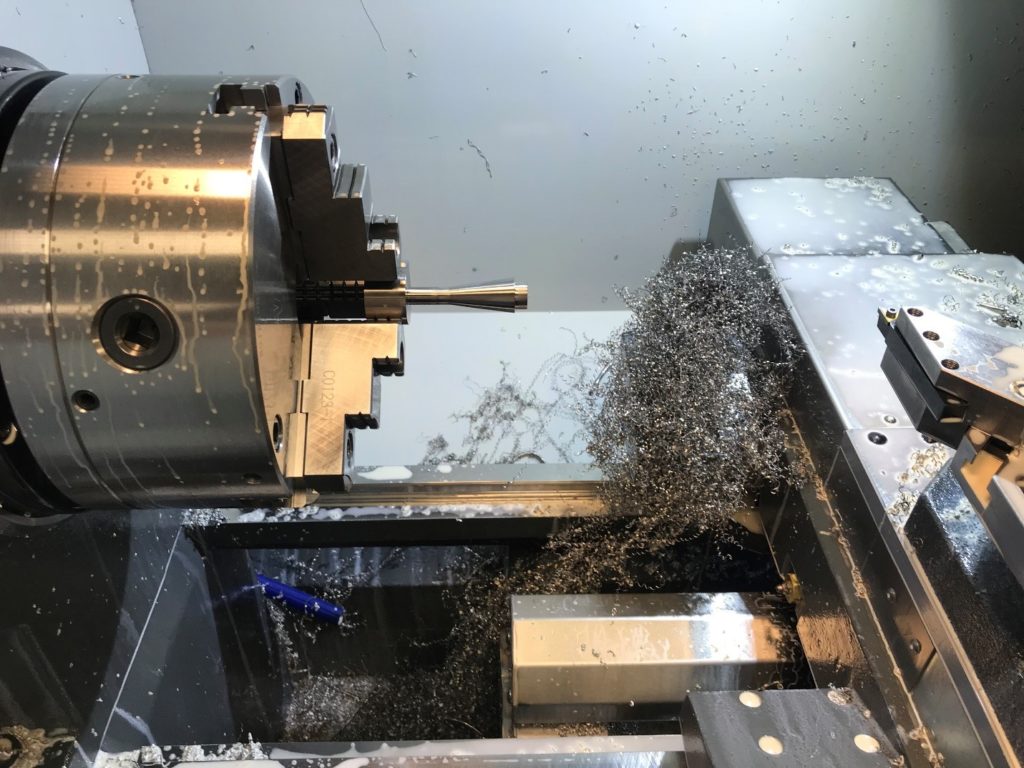

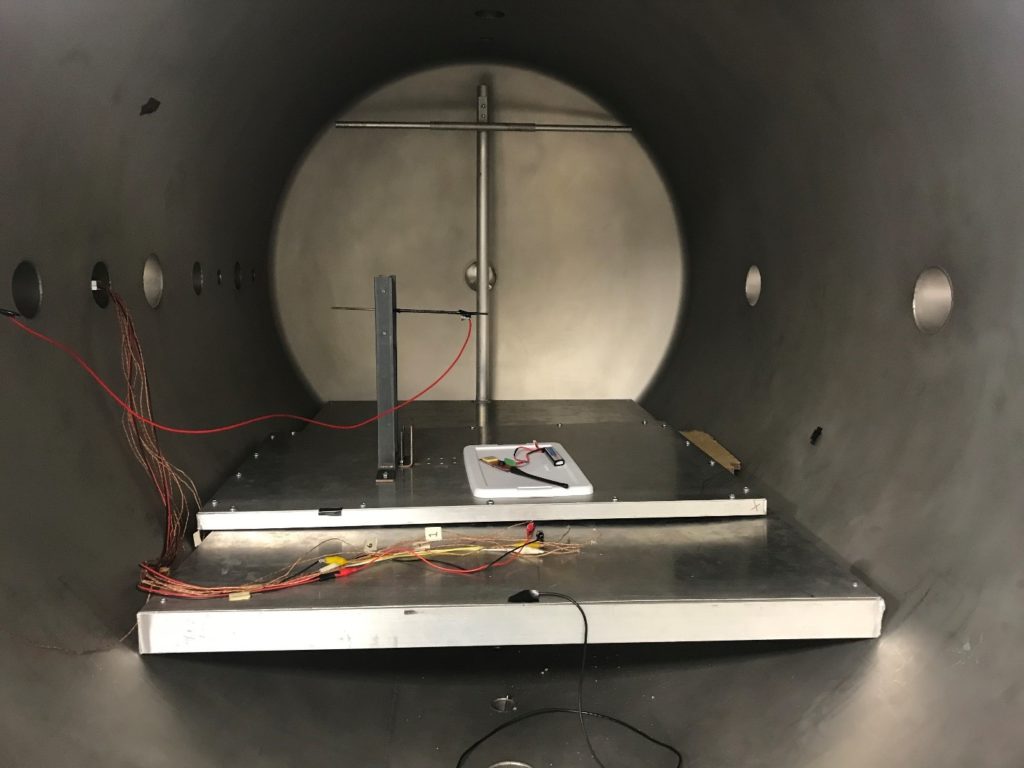

To join this project, our team had to submit a resume and letter of recommendation to Honeywell to get an interview. Our team consists of six Embry-Riddle students, our mentor Dr. Dorfling, as well as multiple Honeywell engineers. The major job of our first semester was to submit a survey to Honeywell that included a design of our drone, flight test plans, wind tunnel test plans, and a characterization of our drone compared to previous UAM designs. During the second semester we built our UAM, and 3-D printed a compartment designed to better help predict and characterize UAMs similar to ours.

Due to Covid-19, our project was not finished over the school year and got pushed into our summer internship. As a result, our internship was conducted virtually, and our project’s progress was slowed. But over the summer, small test flights took place along with error analysis, and I worked with Honeywell Aerospace’s Electrical Power Group in Torrance, California on the Next Generation Jammer Program (NGJ). My work with the NGJ tested mid band as well as low band performance calculation of the Ram Air Turbines Generation (RATG).

Over this summer of 2020, Bell conducted the first customer flight test of UAM designs our team worked on, and I can see where the research my team and I are doing will be implemented in the future. Our team’s UAM project will continue over the 20/21 school year and will include our first test flight. That will allow us to analyze the data to predict the optimal flight takeoff and landing paths for our UAM design. The upcoming Honeywell UAM Team will include a mix of returning team members as well as new juniors to finish off the project. Once our project is finished up the same process will be restarted with another UAM type, and could include multirotor, fixed wing, or rotating rotor designs.

The experiences I gained with my team and during my summer internship has been amazing. Working on this project has allowed me to apply what I have learned from the classroom and to see how our work will change transportation around the world. Our internship has also allowed me to experience Honeywell’s corporate environment and further my understanding of UAM. I have enjoyed this project and would highly recommend this opportunity to anyone!