by Grace Day

Hi! My name is Grace Day, and I am a senior Aerospace Engineering student here at Embry-Riddle, Prescott. On campus, I am involved in the Alpha Xi Delta sorority as the former Member Development VP, the Membership VP, and most recently the Chapter Life VP. I also am a part of the Women’s Ambassador Program as the Treasurer and former Public Relations VP. I work part time (up to 25 hours a week) as a Campus Ambassador, a tour guide, for the admissions department and I am a TA/grader for a few engineering classes. On top of my work, full engineering course load, and some sleeping, I am also still a part time intern for Lockheed Martin Space in Waterton Canyon, Colorado.

Me, taken at Lockheed Martin (mask removed only for photo)

Me and my sorority sisters, taken fall 2019 (pre-COVID)

I have spent my past summers as an engineering intern at companies like Northrop Grumman and Lockheed Martin gaining valuable experience and making lifelong friends. I spent the summers after my freshman and sophomore years in Redondo Beach, California working as a Systems Engineering Intern for Northrop Grumman and this past summer as a System Engineering Intern for Lockheed Martin up in the Denver area. I was fortunate to be able to work in person during the pandemic, however it was a much different experience than my previous internships.

For starters, I was the only intern in my area while most of my coworkers were at least a few years out of college. Many people worked part time from home, but my work required I be in the office on special computers, meaning somedays I was the only one in until lunch. I also supported a very fast paced, always changing team that focused on system architecture. Architecting a space system is not an easy thing, it requires so much background knowledge and experience, something I did not have. Before the summer started, I reached out to my manager asking what I could do to best prepare for my summer in Denver. My manager suggested I learn a program called Systems Tool Kit, or STK. The program is a modeling software for any and all types of systems from airplanes, to submarines, to spacecraft. The company offers free online training and licenses for students and professionals, so I jumped on it right away. This was all right after COVID-19 shut down our university and allowed me a bit more free time to focus on learning STK.

STK offers three levels of training from a basic understanding of the software to very specific situation-based modeling protocols. I chose to do it all. The first certification took me about one week to learn and consisted of an 8-hour exam at the end. I passed this course and moved on the intermediate level, which took me a bit longer. Right before I started the second level STK posted a blog announcing the first 100 people to pass the exam would win a free t-shirt with the logo. I jumped right into the training and after two weeks of learning I took the next 8-hour exam and passed (and got my free t-shirt).

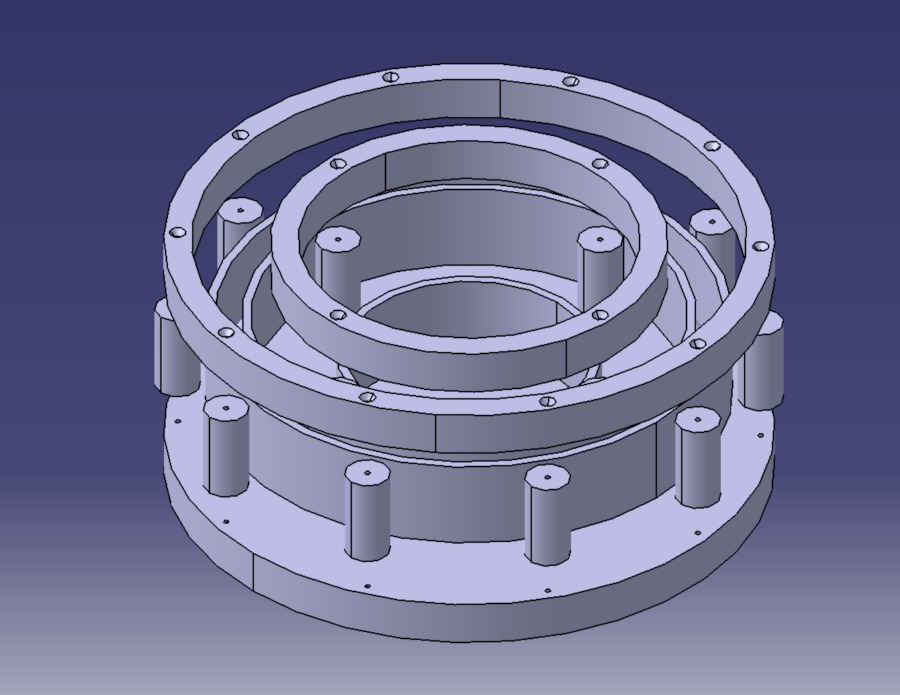

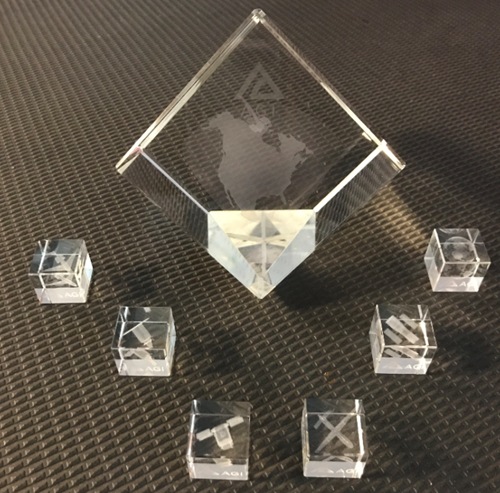

The last certification is student’s choice where you pick four of seven categories to master. The seven track options are Track 1: STK Essentials, Track 2: Analysis Workbench, Track 3: STK Coverage, Track 4: Aircraft, Track 5: Communications, Track 6: Spacecraft Trajectory, and Track 7: Space Environment. I chose to pursue tracks 3, 5, 6 and 7 because they were most applicable to my job and my interests. It took me about 4 days to student for each one and a 4-8 hour exam at the end. As I passed each one, I got a small cube, shown in the image. One I passed all four required for the last certification, I was awarded with the large glass cube, a certificate, a pin, and a lanyard.

From doing this course, I was extremely prepared to go into my internship as a useful employee, and help my team win many proposals. Even now as a part time intern through this school year I have been able to help out whenever I can.

I just signed my full time offer to be a System Engineer at Lockheed Martin with my same team and am very excited to be moving up there in May of 2021! It has been an amazing almost four years here at Embry-Riddle and am so happy for the education I have.

Thank you so much for reading about preparing for internship during COVID-19!