by Mayra Bibiano

My name is Mayra Bibiano, a B.S. in Aerospace Engineering – Astronautics major at Embry-Riddle, and from May 3rd to 5th I went with the VEX Robotics Gold team to compete at VEX Worlds 2022 in Dallas, Texas for the first time since 2018. Yet the team’s road to Worlds was a lot more complicated than you think, so how exactly did we get there?

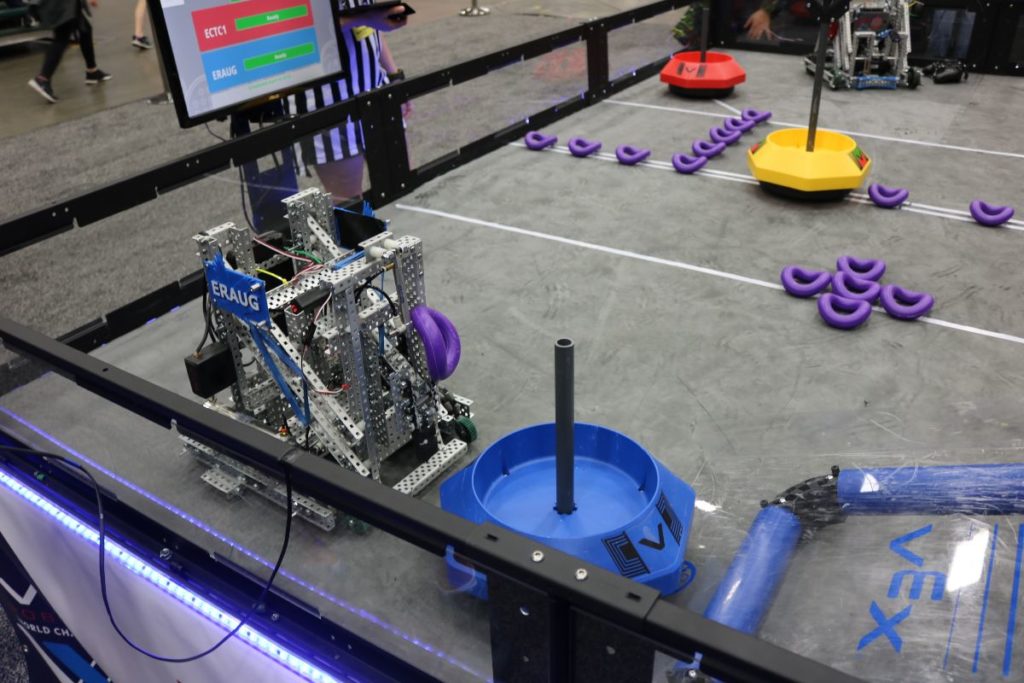

If you don’t know, VEX Robotics is a club on the Prescott campus, with a Blue Team [ERAUB] and a Gold Team [ERAUG], that allows students from different majors and years to collaborate with one another to build and program two separate robots to compete with other teams in VRC (VEX Robotics Competitions). These competitions change year to year and this year, the competition was called Tipping Point. Two teams compete against one another to gather the most points on a 12-foot by 12-foot field. Each round is 2 minutes with a 45-second autonomous period and a 1-minute and 15-second driver-controlled period. Teams compete to score points by stacking rings onto mobile goals and by balancing these goals and/or the robot on a central platform. Teams can also earn bonus points from higher scores in the autonomous period.

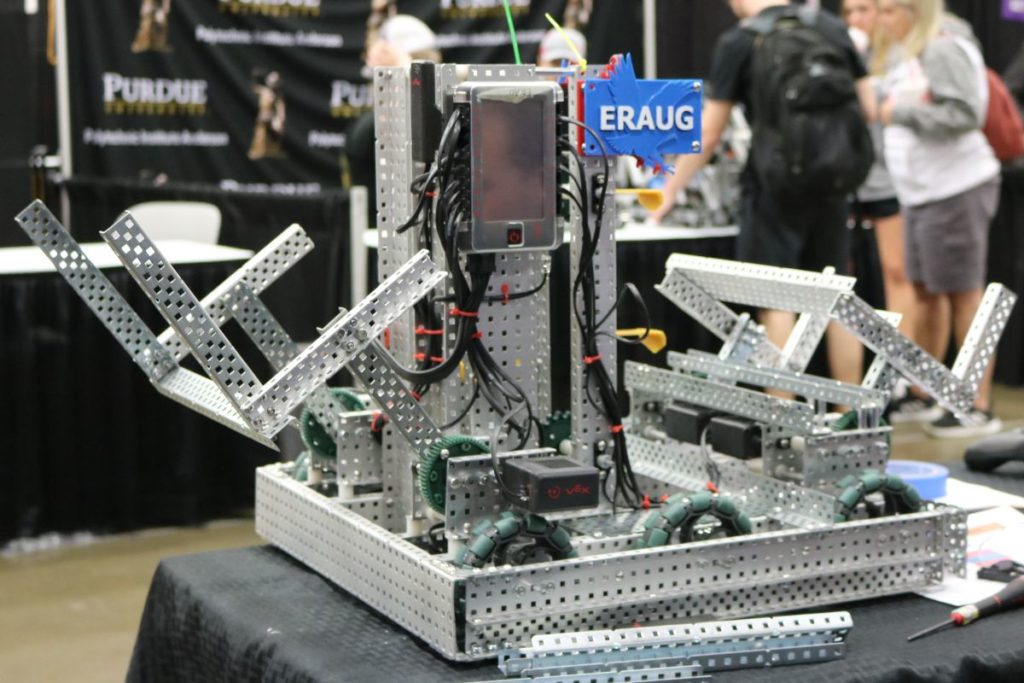

Our ERAUG team made two robots: the smallest robot, Jeef, was a robot that lifted mobile goals with pneumatics as well as getting onto the platform itself. Our bigger robot, Berky, was designed to get rings into the mobile goals that were around the field.

Once the spring semester rolled around, we were ready for our competition. Our first ever competition for the 2021-2022 school year was held on March 5 at the ERAU (Embry Riddle Aeronautical University) Prescott Campus. Our ERAU Gold Team won Tournament Champions, the Excellence Award and the Design Award. Under normal circumstances when seven teams attend our competition, we would have automatically gotten a spot at Worlds, but because we only had five teams in the competition we were not selected.

During that competition, our team attempted the Skills Challenge, where the two robots try to score as many points as possible without another team on the field. From this, we ended up ranking 33rd on the VEX U World Skills standing. From here we found out that if we ranked higher, we would be able to get a spot in Worlds. The team decided to practice getting a better skill score to secure our spot at Worlds and on March 15 we were given the opportunity to do another skills challenge and ended up improving by over 50 points. With that, we waited to see if we were given an invitation. Four days went by, and we got the best message from our president: “We are going to Worlds!!” The whole team was ecstatic because we did it without even knowing we could make it, but we did! After that day, we excitedly spent the whole month completely rebuilding our robots so that they would be Worlds ready.

The first day of Worlds was just checking in, practicing and fixing anything just in case the robot moved a lot on the trip to Dallas. The next day was the first day of matches. That day was the most stressful and exciting day of the whole week. Our first three matches, losing two and winning one, really got us into a flow where we realized there were inconsistencies in our build and our program. From there we practiced nonstop. The only time we got a break was during lunch because the whole day was changing batteries, grabbing tools, grabbing robot plates, running to a practice field, running back to the match fields and so on. After that day, winning two out of six matches, we finally had time to breathe and think about how we could improve the next day.

That last day came, and I told everyone before we started our three matches, “No matter what happens today, let’s just have fun.” We won our first match of the day by 100 points and got off to a great start, but then ended up losing our last two matches. We may not have won most of our matches, but I know that those last couple of matches were the most fun we had the whole time. Not worrying about winning was such a good way to renew our energy and just have fun.

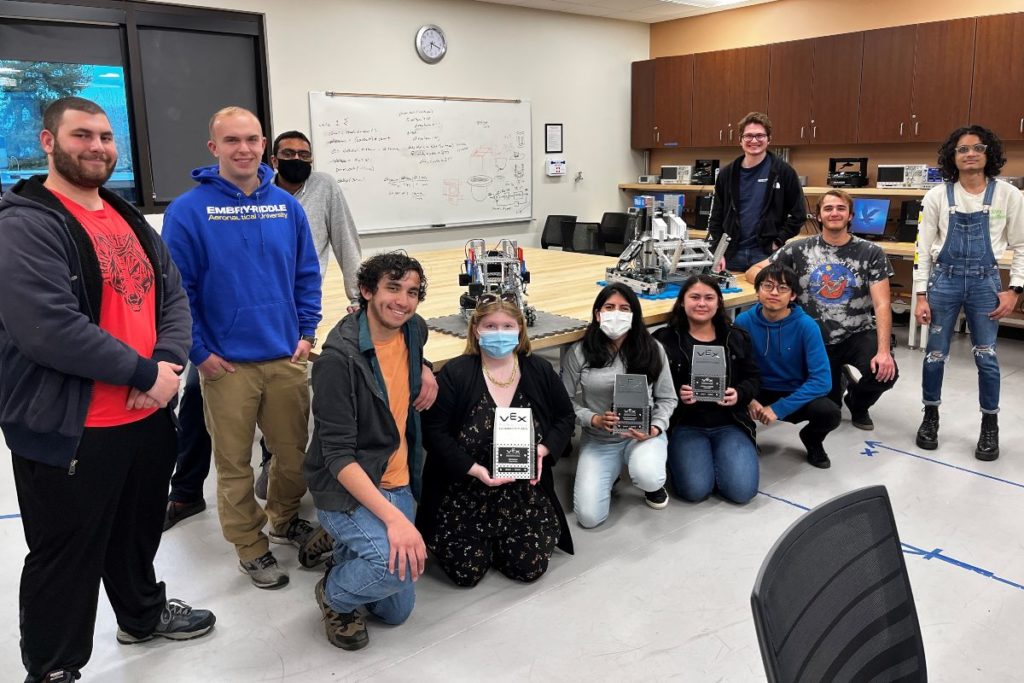

We ended up placing 30th of 37 teams in our division as well as ranking 25th in the skills standing. Looking back on our work this past year, and in years past for a lot of the team’s members, we are so happy with the experience we had at VEX Worlds. Our team gained a lot of problem-solving, time management and teamwork skills while working under pressure. With this, I know the team will be in good hands in the years to come with this experience.

I am currently a 4-year Aerospace Engineer student and graduating in December 2022 and this will be my 4th year in the VEX Robotics club and the 2021-2022 year I was the Team Lead. When I first joined the team I was interested in building robots because I had done it in middle school, but now it’s just a fun hobby and working with the team is always very fun. This club has allowed me to work on my team collaboration, organizational skills, leadership skills, and project management which will help me in the industry.

If students decide to join the VEX Robotics club, we teach students how to build and program a robot. You don’t even have to be in a similar degree. Because of all the hard work the team has done throughout the years and the experience we have gained, we were able to go to Worlds. I know that in the coming years our team will be well cared for. I cannot express how proud I am of the team as well as how grateful we are for the experience.