by Kylie Cantrell

My name is Kylie Cantrell. I am a student at Embry-Riddle Aeronautical University – Prescott Campus, earning my degree in Forensic Biology with a minor in Security and Intelligence Studies. I chose my major because I have always been fascinated with forensics. I took a forensic science exploratory in the 8th grade and have always had the goal to learn more about the field.

In the summer of 2022, I interned for Freeport-McMoRan at the Climax Mine in Leadville, Colorado. My title was an Industrial Hygienist for the Health and Safety Department. At Climax, I learned how to sample heavy equipment (haul trucks, graders, loaders, drills, etc.) for dust, silica, and diesel particulate matter (DPM) in the cabs. My project was to study the ventilation systems in the heavy equipment during sampling to see if I can make the air cleaner in the cabs for the operators. I used SKC Airchek Pumps with several kinds of filter cassettes to test for the particulates in the air. I wrote notes about the weather, the condition of the equipment, where the sampling pumps were set and anything else that may be important to note. After the sampling period is over, the cassettes are sent to the lab. Documentation such as the pump number, notes taken in the field and results are all added to software called Cority.

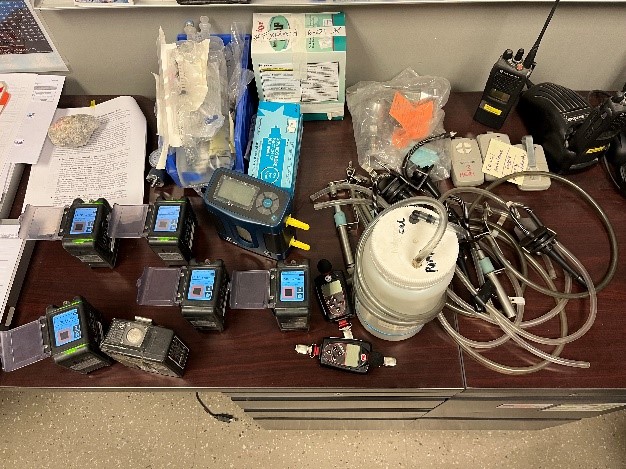

When sampling the mine for dust/silica and DPM, I would normally choose 3 pieces of heavy equipment per sampling day. In the image here, the tubes on the right are attached to the cyclones that hold the media that trap the particulates I am testing for. The large white container is what I would use for calibrating the pumps. There is a blank filter on a cyclone inside with one tube connected to a pump. The other is connected to the calibrator (the device with two yellow caps). There are also dosimeters in the picture which are placed on the shirt collar of an operator to check the noise levels they are exposed to while operating the equipment.

The reagent we used releases carbon disulfide which can be harmful to Climax employees. The pump above the launderer has a 226-01 filter that traps the carbon disulfide as the pump runs. The sampling period is approximately 5 hours, and the results are sent to a lab for analysis. In the images above, I am holding a Photo-Ionization Detector (PID) that measures the carbon disulfide in the air and gives immediate results. Both methods are used because the pump will sample over a longer period, whereas the PID gives real-time data. Since the molybdenum is not flowing in the launderer at a constant rate, the carbon disulfide levels can differ within a couple of minutes or a few hours. It is important to see both sets of data.

The classes at Embry-Riddle that really helped me were Instrumental Analysis and Trace Evidence, Biochemistry, Human Anatomy and Physiology, and General Biology and Chemistry. Trace Evidence prepared me to write a chain of custody on all the samples turned into the lab. Biochemistry was useful in understanding how the human body reacts with different minerals being inhaled such as elemental dust and silica. Anatomy and Physiology gave me a basic understanding of how silicosis forms and affects the alveoli in the lungs. General Biology and Chemistry are important for any industrial hygienist to know the basics. Although my internship did not pertain to forensics, I was able to put my major and minor to use. I also got to learn a lot about the mining industry and work around some very cool trucks.

This experience has opened my eyes to new possibilities and I really enjoyed my time at Climax. I am very interested in the mining industry and I would love to continue with Freeport-McMoRan after college. I enjoyed working with so many people from different departments and working together towards one major goal. There is always something new to learn in mining!