by Daisy Hatcher, Forensic Biology

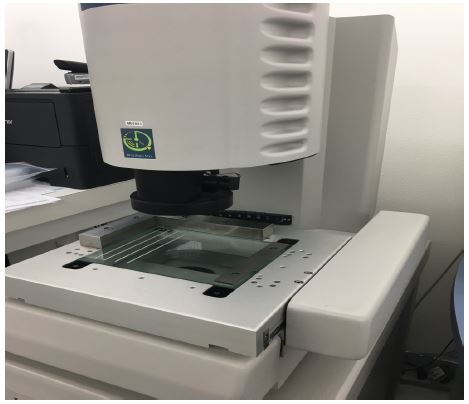

This summer I interned at Rolenn Manufacturing, Inc. from May to July. Rolenn is a medical device manufacturing company that specializes in making parts for medical devices and implants. They work with many customers internationally making parts for devices that will eventually help save people’s lives. My role at Rolenn Manufacturing was an inspector. As an inspector, we have to inspect all the parts that are shipped by Rolenn. My specific role as an inspector was to inspect a part known as 60000591-001, known as 591’s for short. This part is extremely small, with a diameter of about 1.880 mm to 1.910 mm to be exact.

I also learned the process of the stages of inspection and how to fill out the related Quality Assurance paperwork. While I only did the final inspection for the parts at Rolenn, I did learn the overall process of production and inspection. I was trained and involved in the inspection and shipping part of the process. Inspection involved using a microscope and computer to measure dimensions of very small parts. Once the parts were inspected, they were cleaned and shipped with 70% isopropyl alcohol and 30% deionized water. The parts were then weighed and averaged to make sure the correct amount was being packaged and sent to the customer.

To complete the process, the parts are shipped by the inspection department along with all the associated quality assurance paperwork. I learned that it takes many people and pieces of a puzzle to ft together to have this process run smoothly. The classes I have taken at Embry-Riddle really prepared me for work assignments. At Rolenn, we had to keep up with due dates which parts had to be shipped out. Organizational skills and rules I learned int he lab helped me to prepare for this internship.

My experience with the cooperative education/internship program at Embry-Riddle was great. All of the assignments made sure I was getting the most out of my internship experience and helped me along the way. The learning objectives we had to prepare beforehand were extremely helpful in guiding me in the direction I wanted to go throughout this internship. They allowed me to set goals that I wanted to achieve while interning and kept me accountable. The reports have allowed me to share what I have learned over the summer. I enjoyed everything that came with this internship and it showed me that I am more than ready to start a career working in a lab environment.